Property History

Coal exploration began in the 1960s, identifying an estimated potential of approximately 15 million tonnes of raw coal.

Exploration resumed in the early to late 1990s, with additional drilling increasing the estimated potential to approximately 20 million tonnes.

From 2013 to 2019, North Coal completed further exploration in the area significantly expanding the geological understanding and identifying potential coal volumes of up to 150 million tonnes.

We are stewards of the land and must always keep in mind that actions today impact how future generations will use and enjoy the land. It is our acceptance and responsibility of this principle that guides our mine development. It is with this in mind that we are taking a comprehensive and holistic approach to all aspects of our operations and are considering closure at the beginning.

Our approach includes early and ongoing discussions with local communities and Indigenous peoples. It includes building environmental protections into the mine design. It includes creating safe, family-supporting jobs for hundreds of people. It includes mining quality, high-grade steelmaking coal that will be used to build hospitals, schools, and bridges, to name a few. Steel that will be critical to our transition to a renewable economy.

The Michel Coal Project began by bringing water and mining experts with experience from around the globe together to propose designs that would protect the environment and generate strong economics. Many designs were explored and refined. The result is an economically strong mine design that protects water quality, minimizes dust generation, and returns habitat to wildlife throughout the mine life by using innovative globally proven technologies.

Michel Coal Project

The Project is a proposed open-pit metallurgical coal mine targeting high-quality steelmaking coal and has a substantially advanced geological database, engineering designs, and environmental assessment.

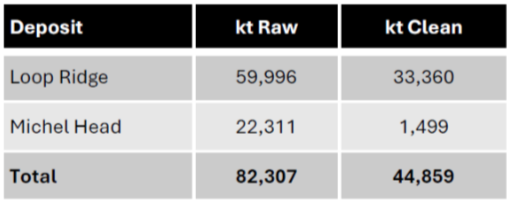

Extensive exploration drilling database validating a 123 million tonne raw coal resource and 45 million tonnes of clean coal reserve

Project design and engineering completed to a pre-feasibility level

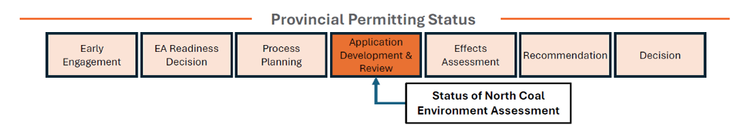

Environmental Assessment advanced to the Application Development and Review phase under the Environmental Assessment Act 2018, Government of British Columbia, Canada

Metallurgical coal product with a coke strength after reaction (CSR) of 67

Sustainable and consistent annual production rates of 2 million clean tonnes per year over a mine life of 25 years

Significant employment and career opportunities

Adjacent to existing coal mine operations

Access to established and reliable rail, port, roads, and energy infrastructure

Independent reviews concluded the Project is technically sound and permittable

Ongoing engagement with local communities and First Nations

Environmental Process & Management

North Coal recognizes the environmental sensitivities and technical challenges of operating in the Elk Valley and has embedded environmental considerations into mine design from the outset of project planning. The Company’s approach is grounded in modern mine design and mitigation-by-design principles, with an emphasis on reducing environmental interaction, managing risks at the source, and integrating environmental controls directly into project layout and sequencing.

Water Protection

The management, monitoring, and protection of freshwater resources are central to North Coal’s environmental strategy. Water protection has been a guiding element of project development since 2013 and continues to inform mine design and operational planning. North Coal is committed to meeting the objectives and targets established under the Elk Valley Water Quality Plan (EVWQP).

The Company’s water management approach is based on the principle of keeping clean water clean and minimizing contact between water and mine materials. This is achieved through a multi-layered strategy that includes diverting surface water around mine facilities to reduce mine-water interaction, implementing passive water treatment measures such as saturated rock fills (SRFs) and suboxic rock storage to limit the mobilization of constituents of concern, including selenium, and applying active water treatment where required prior to release to the environment.

Long-term planning is incorporated through the development of engineered landforms designed to replicate natural processes, supporting stable ecosystems while inhibiting the movement of selenium and other constituents of concern. Mine design has specifically responded to peak selenium loading scenarios identified in the EVWQP by prioritizing source-control measures.

Air Quality Protection

Air quality protection is addressed through mine design and construction practices that reduce dust generation during operations. The mine rock storage facility (MRSF) is planned to be constructed from the bottom up using shorter, staged lifts rather than large single-lift dumps, improving stability and limiting dust emissions.

This construction approach allows progressive reclamation to occur concurrently with mining activities. Reclaimed surfaces can be established earlier in the mine life, supporting dust suppression, improving air quality, and creating vegetated landforms that contribute to wildlife habitat and movement corridors over time.

Reclamation & Closure

Reclamation and closure planning are fundamental to North Coal’s approach to mine design and land stewardship. The Project is planned from the outset with the objective of returning land to safe, stable, and productive post-mining uses that support traditional and recreational activities such as hunting, fishing, gathering, trapping, and recreation.

Closure considerations are integrated throughout project development, with long-term landform performance and ecological function guiding both design and operational decisions. By planning for closure early and implementing reclamation progressively, North Coal aims to minimize long-term disturbance and support the timely return of land to natural and sustainable uses.

Community Engagement & Employment

North Coal is committed to open, transparent engagement with Indigenous Nations, local communities, and other interested parties throughout the life of the Project. Engagement activities are designed to support informed participation, incorporate local knowledge, and ensure project development reflects community input.

Public engagement will include open houses, working sessions, and regular updates, with a focus on supporting the Environmental Assessment process and maintaining clear communication as the Project advances.

The Project is expected to provide meaningful employment opportunities during both construction and operations, supporting long-term economic participation in the region. North Coal anticipates up to 500 construction jobs over an 18–24 month period and approximately 300 long-term operational jobs once in production. The Company prioritizes local hiring where possible and is committed to fostering a diverse, inclusive, and safety-focused workforce that supports current and future generations in the Elk Valley.

Carbon Strategy

Mining plays an important role in the global energy transition by supplying materials required for decarbonization, including steel and the metallurgical coal used in primary steel production. Reducing greenhouse gas (GHG) emissions from mineral extraction and processing represents a significant opportunity for the mining sector to contribute to climate objectives, particularly given the industry’s share of global emissions.

North Coal’s carbon strategy is informed by both product characteristics and mine design. The Project is expected to produce a premium mid-volatile hard-coking coal with high coke strength after reaction (CSR), a product that supports efficient blast furnace operation and reduced coke consumption in steelmaking. Product quality is therefore an important consideration in the broader decarbonization of the steel value chain. North Coal’s objective is to produce this coal with the lowest practicable carbon intensity, through design choices that reduce energy use, emissions, and material handling requirements.

In 2021, North Coal partnered with the Bradshaw Research Initiative for Minerals and Mining (BRIMM) at the University of British Columbia to undertake detailed project-level carbon emissions modelling. This work is informing mine design, sequencing, and infrastructure options aimed at minimizing emissions, with the objective of achieving net-zero Scope 1 and Scope 2 emissions. North Coal also recognizes the importance of Scope 3 emissions and is engaging with industry and research partners to support downstream emissions reductions through the supply of high-performance metallurgical coal and alignment with evolving steel decarbonization pathways.

Resources & Reserves

Significant progress has been made in advancing the permitting of a proposed 1.8 million tonnes per annum (Mtpa) mine plan incorporating the Loop Ridge and Michel Head resource areas.

A Preliminary Feasibility Study completed in 2022 delineated a conventional open-pit mining operation with an anticipated mine life of approximately 23 years. The study integrated mine design, production scheduling, and supporting infrastructure across both deposits, providing a robust technical basis for the Project and supporting continued advancement of permitting activities.

Reserve Table

Links & Affiliations

-

Circulor Ltd.

ESG and CO₂ TRACKING

North Coal’s partnership with Circulor advances transparent and responsible steelmaking by enabling real-time tracking of CO₂ intensity and key ESG metrics across the supply chain. This collaboration supports North Coal’s commitment to innovation, environmental protection, and meaningful engagement with Indigenous communities as the industry moves toward net-zero. Through enhanced traceability, North Coal is helping future customers meet rising sustainability expectations and strengthen accountability from project development to end use.

-

University of British Columbia

The University of British Columbia is one of Canada’s leading research universities, recognized globally for its work in environmental science, earth sciences, and resource management. Over the past five years, North Coal has undertaken a range of collaborative projects with UBC and the Bradshaw Research Initiative for Minerals and Mining (BRIMM), including multiple studies focused on greenhouse gas emissions, soil carbon, and environmental DNA (eDNA). These projects support a science-based approach to environmental monitoring and informed project planning.

-

Elk River Alliance

The Elk River Alliance is a regional organization focused on water quality, watershed health, and environmental stewardship in the Elk Valley. North Coal contributes in-kind support to a number of Elk River Alliance initiatives, including participation in the Elk River Monitoring Collaborative, to support regional monitoring efforts and science-based understanding of watershed health.

-

AME BC

(Association for Mineral Exploration British Columbia)

AME BC is the leading industry association representing mineral exploration and development in British Columbia. North Coal supports AME BC through active participation in industry initiatives, with a focus on advancing health and safety practices and sharing practical, on-the-ground experience across the sector.

-

Responsible Steel

Responsible Steel is a global, multi-stakeholder initiative that sets standards for responsible steel and steelmaking supply chains. North Coal is familiar with and informed by the Responsible Steel framework, which supports responsible production practices, transparency, and continuous improvement across the steelmaking value chain.